If I didn’t have enough to do with the living room I thought why not build a shed. To be fair it is just one of those kits that you stick together. Managed to find this nice little pent shed. As it is for the girlfriend got some pink paint to finish it off.

We already have a concrete base at the end of the garden from an old shed so after some cleaning up and cutting back of hedges and plants the base looked good with no damage. I made sure that I had ordered that would fit the base.

So the first job was to paint all the panels, a nice coat of white undercoat then 2 coats of the pink.

I have a pretty much endless supply of used pallets at work and bought a long one for this project. Cut a couple of pieces off and made some window ledges. Then painted them up as well as all the trim in white.

Next job is getting the base down. There are 3 struts on the bottom that keeps it off the ground. I wanted to add some extra stability so added another few supports.

Next, I gave these a coat of primer and a couple of coats of weatherproof paint. I don’t know how much effect this will have but just hoping it will slow the rotting process.

Now Putting the back and both sides on followed by the roof. Need to do a small bit of tree surgery to move an overhanging branch, put the front on then tarp the front up and off to bed.

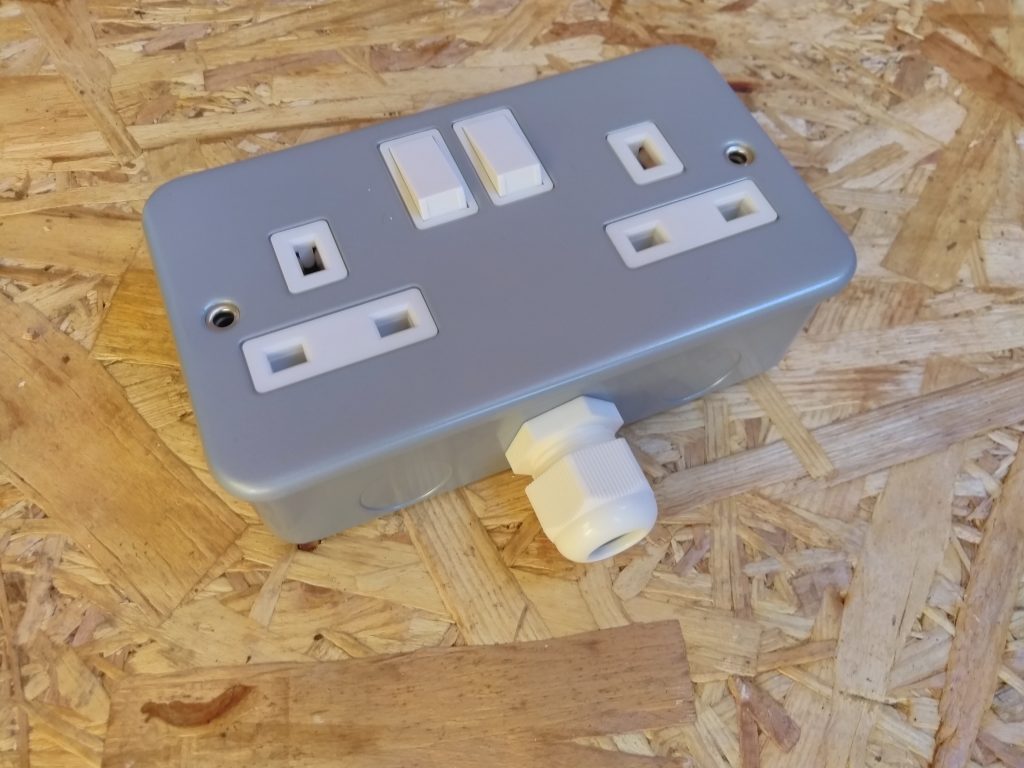

Next day and running some power. I run a power cable through 25mm plastic trunking. I don’t need a lot of power, just going to have 2 plug sockets. A string of outdoor lights and an internal led light strip. Possibly another outdoor light but haven’t decided yet. So I’m running this as an extension connected to an rcd plug in the kitchen.

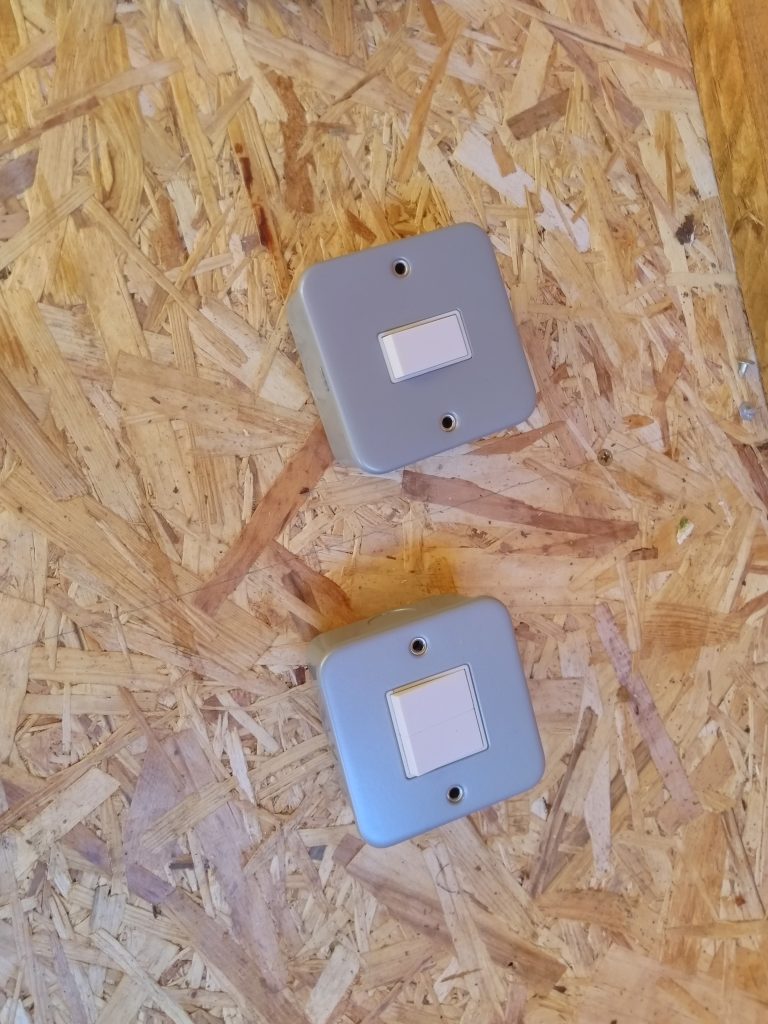

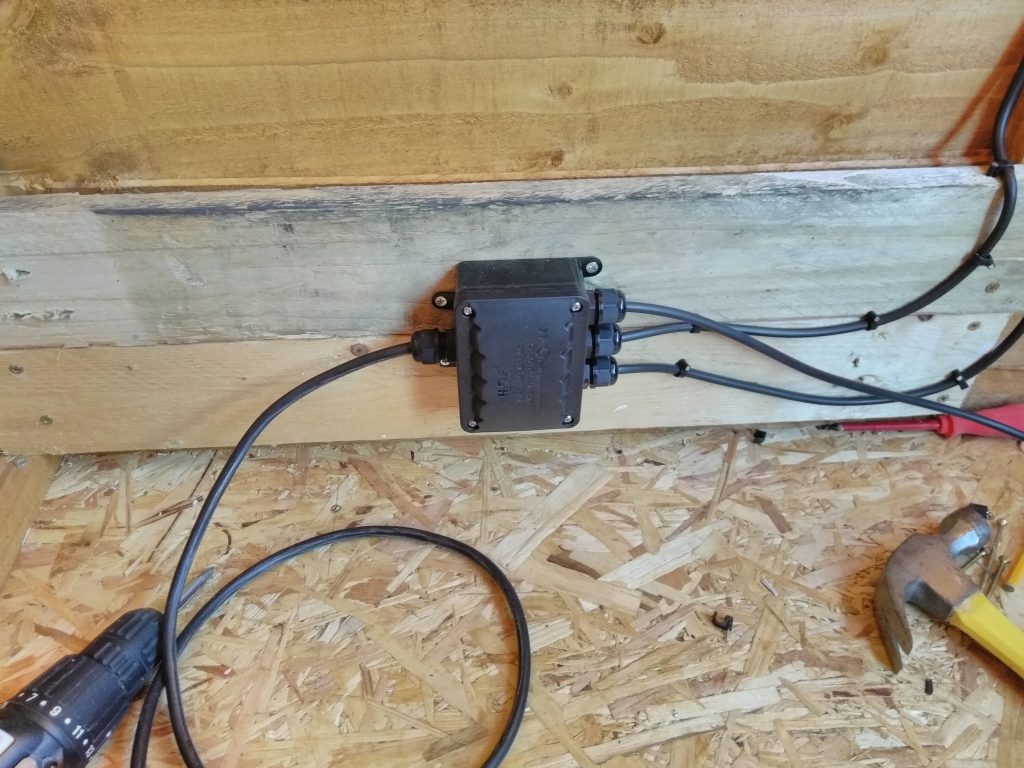

I ordered these Metal Clad sockets and these some waterproof glands and a waterproof junction box.

I used some more of the pallet to make a stable surface in the shed for both the socket and junction box. Then fitted all the cables in the shed. Also fitted a small panel to hold the light switches.

Finishing off some of the outside now, fitted the window ledges as well as a trim made from the pallet. I have also attached a string of light around the outside.

So when I lifted the laminate from the front room I kept hold of some of it for just such an occasion. I haven’t finished it with some trim or anything.

With most of the outside done I have now fitted the windows. It came with some plastic windows but I decided to go down to my local glass shop. These places are usually really helpful. I got 2 sheets of tough glass cut to size and some window putty for under £15.

So, for the time being, I have had to fit a door and leave the project for the rest of the year and focus on the living room.

As soon as I get started again I will get another post up.